Ammunition manufacturing bullets shot

There are different types of bullets for black powder guns

Round, Gothic, flat

I will speak only of round bales that such type of balls to choose it templates,

how to make your lead bullets yourself, most methods also

adapt to other forms of ammunition.

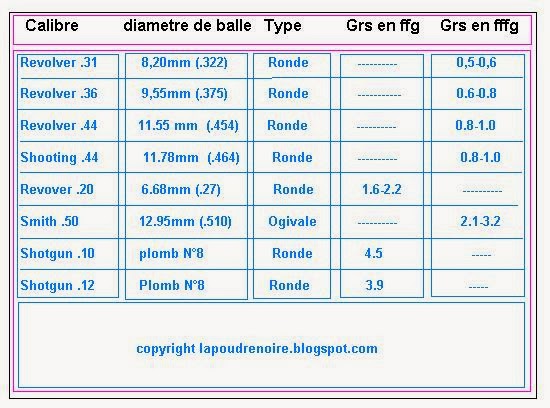

First, here is a table to make sure you use the correct measurement

of balls, follow the instructions in the table below.

It is important that your ball a little strength when you want to

insert into the cylinder chambers and when you push the ball a little

ring of lead should be formed not even 1 mm This indicates that the

ball is firmly seated in the chamber of the barrel.

Here's a sketch:

Molding manufacture bullets

Hardware:

Lead:

For example here I use old lead gas pipe, be sure

best to clean lead before starting to

melt to remove that impurity

Stove:

electrical, gas, or even better

A special furnace for lead:

Molds to make small ingots.

To make a first pass you'll need

In a mold that you can make yourself

With such background bobbin box keeps cutting.

Prior to please wear gloves handling

Here is an example that you can mold

bought in the shops.

The first paggage used to remove a maximum impurity

Before pouring the lead into the mold

A mold.

In this example they s's'agit a .44 caliber mold diameter 454

Double cavity bought 30 € in armory

There are all sizes and shapes of molds you will find

several sites easily on the internet its specialists.

Here are several examples in pictures:

A pair of gloves to protect you from burns and possible projection.

Very important respiratory mask with filter

Beware if you breathe vapor lead

you should know that It

it attaches to your body for life

so be careful not to neglect

Tongs to handle hot items

Ladle with spout, cloth .

Making ingots

Begin to melt your lead.

I have disposed of the lead in the pot outside air that I cover

Meanwhile melt that is what happens after 10 minute

A good faith molten lead poured molten lead

in your molds, taking care not to pay charge,

you should gently pouring it happened

without too much difficulty

As you can see from the pictures,

Lead pay is already very clean and shiny

Let stand and unmold

That's basically what a finished faith is obtained

Beautiful small well-polished bars, the second pass will be

made at the time of casting bullets will still

remove any residues accidentally paid

Molding bullets

Maittez your ingots of lead melting

Spend some time, this is what we get:

The lead is melted and ready to be cast

Grab your pan and move it over a candle or two matches

deposit at the end of the tallow in the mold this will facilitate the release of the balls

Heat up your pan directly on the hob and then directly

In molten lead should it be hot

Well paid your lead with a ladle in each port that has your mold

tap with a piece of drinking the removable part of the mold

Which cuts the excess lead

Unmold and that pretty shot

All in this video for more details

No comments:

Post a Comment